Stainless steel is a type of metal that is well-known for its durability, strength, and resistance to corrosion. It is an alloy, meaning it is made up of a combination of elements, which gives it its unique properties and characteristics. Stainless steel is used in a wide range of applications, including construction, transportation, and consumer products.

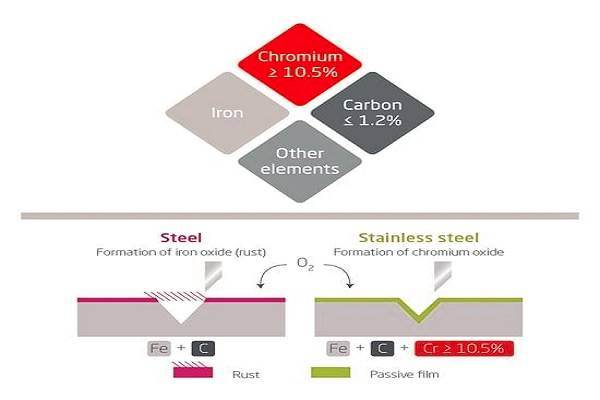

The composition of stainless steel varies depending on the type, but it typically contains elements such as chromium, nickel, iron, manganese, carbon, silicon, molybdenum, nitrogen, and others. These elements work together to give stainless steel its resistance to corrosion, its strength, and its ability to withstand high temperatures.

Stainless steel has a wide range of properties that make it an ideal material for many applications. It is resistant to corrosion, strong, durable, heat-resistant, magnetic, hygienic, and aesthetically pleasing, making it an excellent choice for a variety of uses.

In this blog post, we will take a closer look at the composition of stainless steel, the properties of stainless steel, and the different types of stainless steel. We will also explore the various applications of stainless steel and why it is such a valuable material. Whether you are building a new construction project, designing a new product, or just looking for a durable and attractive material for your home or office, this blog post will provide you with valuable information about stainless steel.

The Elements that Make Up Stainless Steel

Stainless steel is a unique material made up of several elements that work together to give it its unique properties. The most important elements in the composition of stainless steel are:

- Chromium: Chromium is the most important element in the composition of stainless steel, as it is responsible for providing the material with its corrosion resistance. Chromium forms a passive film on the surface of the steel, which helps to protect it from corrosion and staining. The minimum amount of chromium required to provide this protection is 10.5%.

- Nickel: Nickel is another important element in the composition of stainless steel, as it enhances corrosion resistance and improves the mechanical properties of the material. Nickel also helps to maintain the passive film formed by chromium, making it an essential component of stainless steel. The amount of nickel added to stainless steel can range from 2% to 10%, depending on the desired properties.

- Iron: Iron is the main component of stainless steel, making up the majority of its composition. Iron provides the strength and durability of the material, and it is what gives stainless steel its magnetic properties.

- Manganese: Manganese is added to stainless steel to improve its hardness and toughness. Manganese also helps to stabilize the austenitic structure of the steel, which is important for its ability to resist corrosion.

- Carbon: Carbon is added to stainless steel to improve its strength and hardness, but too much carbon can cause the material to become brittle. Carbon is typically added in small amounts, ranging from 0.03% to 1.5%.

- Silicon: Silicon is added to stainless steel to improve its resistance to heat and oxidation. Silicon also helps to improve the stability of the steel, which is important for its ability to resist corrosion.

- Molybdenum: Molybdenum is added to stainless steel to improve its corrosion resistance, especially in high-temperature and high-pressure environments. Molybdenum also enhances the strength and hardness of the material, making it an important component of stainless steel.

- Nitrogen: Nitrogen is added to stainless steel to improve its strength and corrosion resistance. Nitrogen also helps to stabilize the austenitic structure of the steel, which is important for its ability to resist corrosion.

Other elements may also be present in smaller amounts, including copper, titanium, and niobium. These elements enhance specific properties of the material, such as its resistance to corrosion and its mechanical properties. The amount and type of these elements will depend on the desired properties of the stainless steel.

Properties of Stainless Steel

The properties of stainless steel are determined by its composition and the balance of the elements that make it up. Some of the most important properties of stainless steel include:

#1. Corrosion resistance

One of the most important properties of stainless steel is its ability to resist corrosion. This is due to the presence of chromium in its composition, which forms a passive film on the surface of the steel that helps to protect it from corrosion and staining.

#2. Strength and durability

Stainless steel is a strong and durable material that can withstand a wide range of conditions and environments. This is due to the presence of iron in its composition, which provides the strength and durability of the material.

#3. Heat resistance

Stainless steel can withstand high temperatures without losing its strength or becoming brittle. This is due to the presence of silicon in its composition, which improves its resistance to heat and oxidation.

#4. Magnetism

Stainless steel is magnetic, which is due to the presence of iron in its composition.

#5. Hygiene

Stainless steel is a hygienic material that is resistant to bacteria, mold, and other forms of contamination. This makes it ideal for use in food preparation, medical equipment, and other applications where hygiene is a concern.

#6. Aesthetics

Stainless steel has a sleek, modern appearance that makes it an attractive choice for a wide range of applications, including architecture, interior design, and consumer products

#7. Recyclability

Stainless steel is a recyclable material, which makes it an environmentally friendly choice for a wide range of applications.

These properties, along with its versatility and adaptability, make stainless steel an ideal material for a wide range of applications, including construction, transportation, and consumer products.

Types of Stainless Steel

There are several different types of stainless steel, each with its unique properties and characteristics. Some of the most common types of stainless steel include:

1) Austenitic

Austenitic stainless steel is the most commonly used type of stainless steel. It is characterized by its high levels of nickel and chromium, which provide it with excellent corrosion resistance and mechanical properties. Austenitic stainless steel is used in a wide range of applications, including kitchen appliances, cutlery, and medical equipment.

2) Ferritic

Ferritic stainless steel is characterized by its low levels of nickel and high levels of chromium. It is a less expensive alternative to austenitic stainless steel, but it is not as corrosion-resistant. Ferritic stainless steel is used in applications where cost is a concern, such as automotive parts and decorative trim.

3) Martensitic

Martensitic stainless steel is characterized by its high levels of carbon, which gives it its strength and hardness. It is often used in applications where high strength is required, such as in the aerospace and medical industries.

4) Duplex

Duplex stainless steel is a combination of austenitic and ferritic stainless steel. It is characterized by its high levels of chromium and molybdenum, which provide it with excellent corrosion resistance and strength. Duplex stainless steel is used in applications where both corrosion resistance and strength are required, such as in the chemical and oil and gas industries.

5) Precipitation Hardening

Precipitation-hardening stainless steel is characterized by its ability to be heat-treated to increase its strength and hardness. It is often used in applications where high strength and hardness are required, such as in the aerospace and medical industries.

Each type of stainless steel has its unique properties and characteristics, and the type that is best suited for a particular application will depend on the specific requirements and conditions of that application.

Conclusion

Stainless steel is a versatile and durable material that has a wide range of properties and characteristics. It is made up of a combination of elements, including chromium, nickel, iron, manganese, carbon, silicon, molybdenum, nitrogen, and others, which give it its unique properties and characteristics.

There are several different types of stainless steel, each with its unique properties and applications, including austenitic, ferritic, martensitic, duplex, and precipitation hardening.

Stainless steel is an ideal material for a wide range of applications, including construction, transportation, and consumer products. It is resistant to corrosion, strong, durable, heat-resistant, magnetic, hygienic, and aesthetically pleasing, making it an excellent choice for various uses.

In conclusion, stainless steel is a valuable material that offers a wide range of properties and applications, making it an important part of modern life. Whether you are building a new construction project, designing a new product, or just looking for a durable and attractive material for your home or office, stainless steel is a great choice.