Are you planning to install a 100-amp electrical system for your home or business? One crucial factor to consider is the size of the wire you’ll be using.

The wire size determines the amount of current that can pass through it without overheating, which can be dangerous and cause fires.

In this article, we’ll explore the different aspects of the 100 amp wire size, including its gauge, insulation type, and voltage rating, to help you choose the right wire for your electrical installation needs.

Amperage or Ampacity

Before we delve further into the topic of 100-amp wire size, it’s essential to understand the difference between amperage and ampacity. While the two terms may sound similar, they refer to different concepts in the field of electrical engineering.

Amperage, also known as current, is the measure of the flow of electricity through a wire or circuit. It is measured in amperes (A) and represents the amount of electrical charge that passes through a point in a wire per second.

The amperage rating of an electrical device or system indicates the maximum amount of current it can handle safely without overheating or causing a fire hazard.

Ampacity, on the other hand, refers to the maximum amount of current that a wire or cable can carry without exceeding its safe operating temperature.

It is determined by the wire’s size, material, and insulation type, as well as the ambient temperature and the length of the wire run. Ampacity is typically expressed in amperes (A) and is used to select the appropriate wire size for a given electrical system.

| Size of Conductor | The ampacity of the Conductor with a Temperature of 75°C | ||

|

Copper |

Aluminum |

Copper-Clad Aluminum |

|

| AWG 8 |

50 |

40 |

40 |

|

AWG 6 |

65 | 50 |

50 |

| AWG 4 |

85 |

65 |

65 |

| AWG 3 |

100 |

75 |

75 |

| AWG 2 |

115 |

90 |

90 |

| AWG 1 |

130 |

100 |

100 |

| AWG 1/0 |

150 |

120 |

120 |

| AWG 2/0 |

175 |

135 |

135 |

| AWG 3/0 |

200 |

155 |

155 |

| AWG 4/0 |

230 |

180 |

180 |

Understanding Wire Gauge

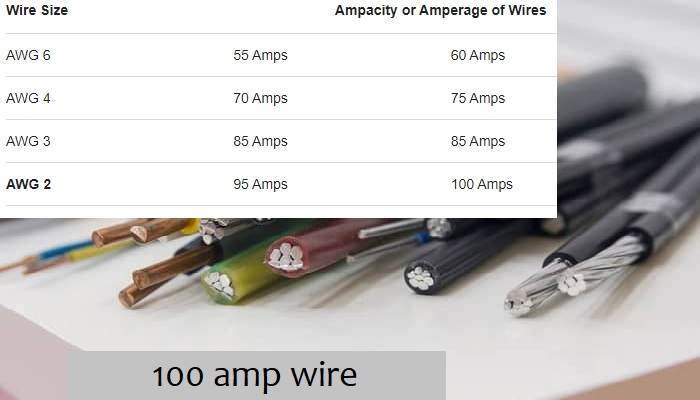

Wire gauge refers to the diameter of the wire, with smaller numbers indicating thicker wires. The American Wire Gauge (AWG) system is the most commonly used standard for wire sizing in North America. For 100-amp applications, the minimum wire gauge recommended is 2 AWG copper or 1/0 AWG aluminum.

These sizes are based on the maximum current-carrying capacity of the wire, which is determined by the insulation type, ambient temperature, and voltage rating.

Insulation Type

The insulation type of the wire determines its maximum operating temperature, which is essential for preventing overheating and electrical fires. The most common insulation types for electrical wires are thermoplastic (THW or THWN), cross-linked polyethylene (XLP or XLPE), and rubber (RHH or RHW).

For 100 amp wire sizes, the most suitable insulation type is THHN (thermoplastic high heat-resistant nylon-coated), which has a maximum temperature rating of 90°C.

Voltage Rating

The voltage rating of the wire refers to the maximum voltage that the wire can handle without breaking down. In the case of 100 amp wire sizes, the voltage rating should be at least 600 volts, which is the standard voltage for most residential and commercial electrical systems.

However, if your installation requires higher voltage levels, such as in industrial or heavy machinery applications, you may need to use wires with a higher voltage rating.

Choosing the Right Wire Size for 100-Amp Applications

Choosing the right wire size for your 100-amp electrical system requires careful consideration of several factors, including the length of the wire run, the load demand, and the type of circuit breaker you’ll be using. Here are some steps to follow:

- Determine the length of the wire run from the main electrical panel to the sub-panel or load center where you’ll be installing the 100-amp breaker. Use a measuring tape or a wire length calculator to get an accurate measurement.

- Calculate the total load demand for your electrical system, including all appliances, lighting, and other electrical devices. Consult a licensed electrician or use an online load calculator to determine the total demand in amps.

- Determine the voltage drop for the wire run, which is the amount of voltage lost due to the resistance of the wire. Use a voltage drop calculator to get an estimate of the voltage drop for the wire size and length you’ll be using.

- Select a wire size based on the total load demand, wire length, and voltage drop. Use a wire size calculator or consult a licensed electrician to determine the appropriate wire gauge for your installation needs.

Choose a wire insulation type and voltage rating that meets the requirements of your electrical system and the local electrical code.

Installation Tips

When installing 100-amp wires, it’s important to follow safety precautions to prevent injuries and property damage. Here are some tips to keep in mind:

- Always use proper safety equipment, such as gloves, safety glasses, and a hard hat, when working with electrical wires.

- Make sure the wire connections are tight and secure to prevent electrical arcing and sparking.

- Use wire connectors and cable ties to organize and secure the wires, and to prevent them from coming into contact with sharp edges or other objects.

- Follow the manufacturer’s instructions and local electrical codes when installing 100-amp wires, and hire a licensed electrician if you’re not familiar with electrical installations.

Real-Life Examples

To illustrate the importance of using the right wire size for your electrical system, let’s consider two scenarios:

Scenario 1: John is installing a 100-amp breaker in his garage to power his new workshop. He decides to use a 4 AWG wire, which he had lying around, to save money. After a few weeks of using the workshop, John notices that his power tools are overheating and his lights are flickering. He calls an electrician, who discovers that the 4 AWG wire is too small for the load demand, causing voltage drop and overheating.

Scenario 2: Sarah is building a new home and wants to install a 100-amp electrical system. She consults a licensed electrician, who recommends using a 2 AWG copper wire with THHN insulation and a 600-volt rating. Sarah follows the electrician’s advice, and her electrical system works flawlessly, providing ample power for all her appliances and devices

The Right Wire Size And Rule Of Thumb

Choosing the right wire size for any electrical application is crucial for ensuring a safe and reliable system.

While there are online calculators and resources available to determine the correct wire size, there are also some general rules of thumb that can be helpful.

One such rule of thumb is that for every 100 amps of electrical current, a wire size of at least 2 AWG copper or 1/0 AWG aluminum is recommended.

For example, a 200-amp electrical service requires at least a 2/0 AWG copper wire or a 4/0 AWG aluminum wire.

It’s important to note that the actual wire size required may vary depending on factors such as the length of the wire run, the type of load, the voltage drop, and the ambient temperature.

Therefore, it’s essential to consult with a licensed electrician or use online calculators to determine the appropriate wire size for your specific application.

In addition to the wire size, the insulation type and voltage rating of the wire should also be considered. Different insulation materials have different temperature ratings, which determine the wire’s maximum safe operating temperature. The voltage rating of the wire indicates the maximum voltage that it can safely handle.

Proper installation techniques are also crucial for ensuring a safe and reliable electrical system.

Using wire connectors and terminals that are compatible with the wire size and insulation type, using conduit or raceways to protect the wire from damage and moisture, avoiding sharp bends and kinks in the wire, and tightening all wire connections to the manufacturer’s specifications are all essential installation techniques.

Choosing the correct wire size for an electrical application is critical for ensuring a safe and reliable system.

While there are general rules of thumb that can be helpful, it’s important to consult with a licensed electrician or use online calculators to determine the appropriate wire size, insulation type, and voltage rating for your specific needs.

Proper installation techniques should also be followed to ensure the safety and reliability of the electrical system.

Conclusion

Choosing the right 100 amp wire size is crucial for ensuring the safety and reliability of your electrical system.

By understanding wire gauge, insulation type, and voltage rating, and following proper installation techniques, you can avoid the risks of overheating, voltage drop, and electrical fires.

Always consult a licensed electrician or use online calculators and resources to determine the appropriate wire size for your specific needs, and follow the manufacturer’s instructions and local electrical codes to ensure a safe and efficient installation.